Robotics & Industrial Automation

In the robotics and industrial automation sector, cable harnesses play a critical role in the reliability, performance, and efficiency of automation systems. Here are some key points explaining the importance of cable harnesses in this sector:

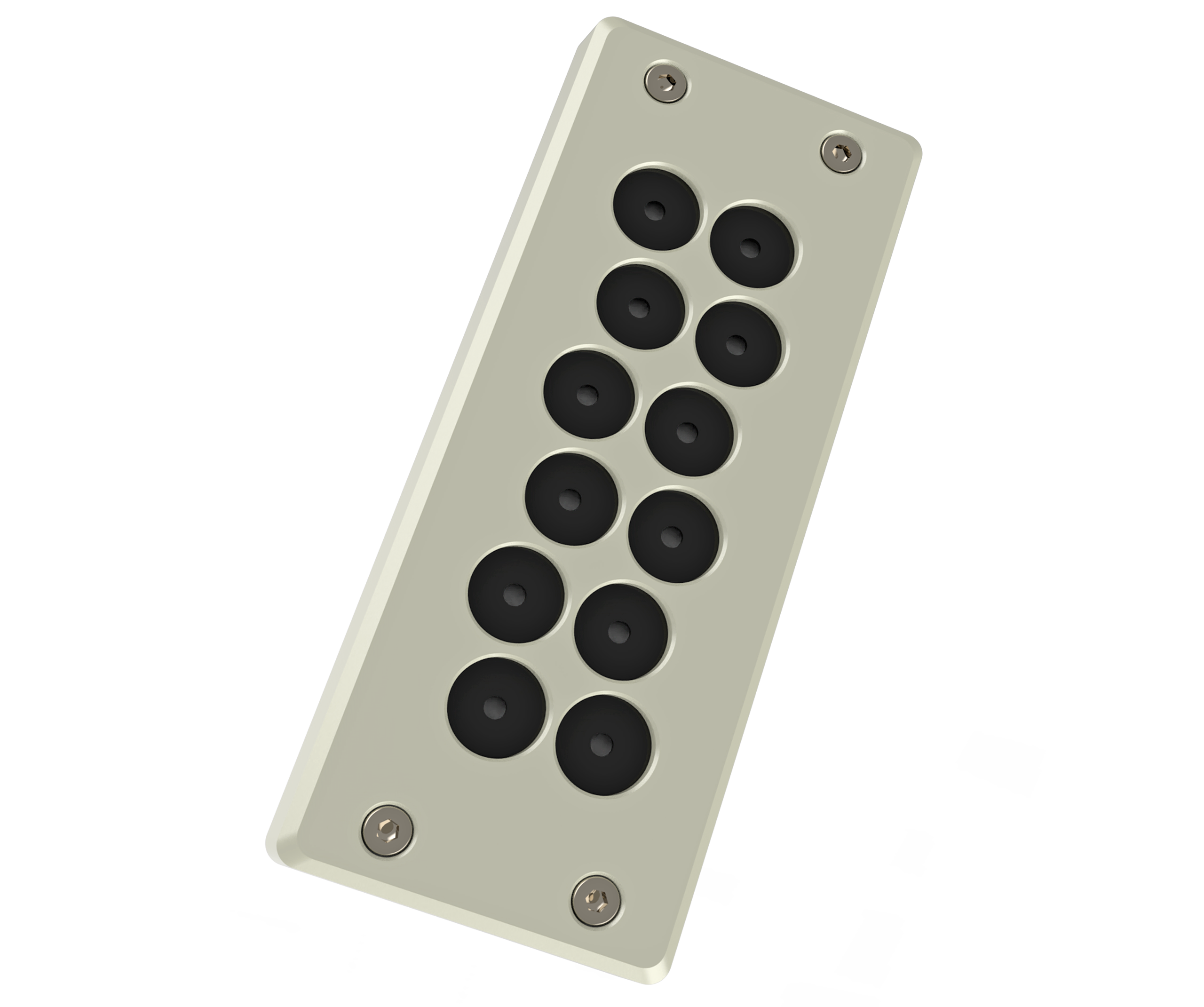

- Cable Management: Robotics and industrial automation systems often have complex cable networks. Cable harnesses keep these cables organized, reducing cable clutter and facilitating access during installation or maintenance. This ensures that systems operate more smoothly and efficiently.

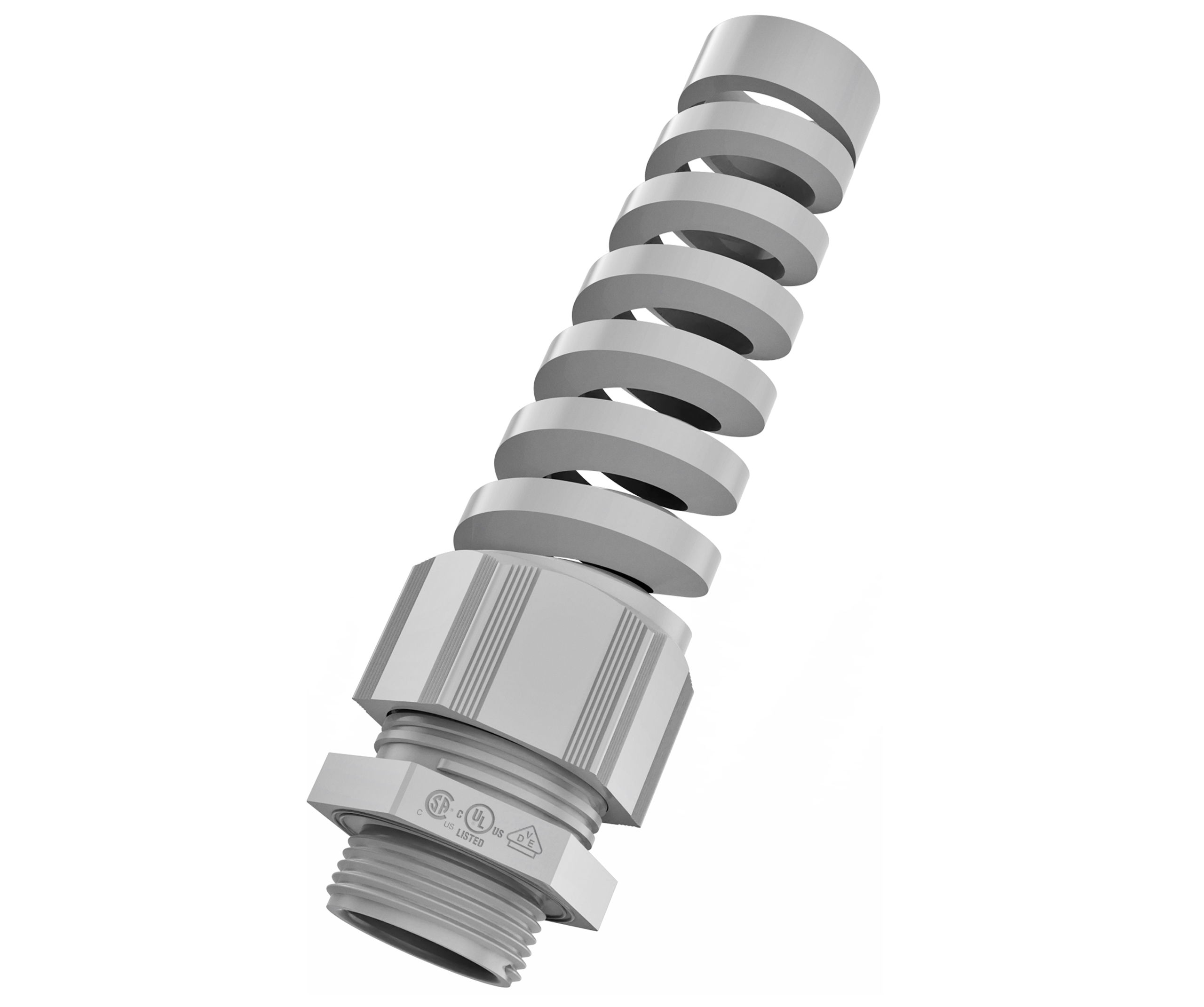

- Protection: Industrial environments can pose potentially harmful conditions for cables, such as abrasion, impact, rain, or chemicals. Cable harnesses protect cables from such external factors and prevent damage. This enhances system reliability and helps prevent failures.

- Safety: Cables in robotics and industrial automation systems often carry high voltage and high current electricity. Properly designed and implemented cable harnesses safely isolate electrical contacts, thereby reducing electrical risks.

- Flexibility and Mobility: Industrial robots and automation equipment are often mobile. Cable harnesses manage the cables of these moving parts securely, preventing cables from being damaged or pinched. This enhances the flexibility and efficiency of systems.

- Maintenance Convenience: Well-installed cable harnesses facilitate maintenance and repair operations. They organize cables and make access easier, allowing for quick access to components requiring maintenance or repair.

In conclusion, cable harnesses in the robotics and industrial automation sector stand out as a critical component for the reliability, performance, and maintenance of systems. Properly selected and implemented cable harnesses ensure that automation systems are more reliable, efficient, and easier to maintain. Therefore, it is important for businesses in the sector to prioritize cable harnesses.

-16-05-2025-09-44-46.png)