Industrial Products

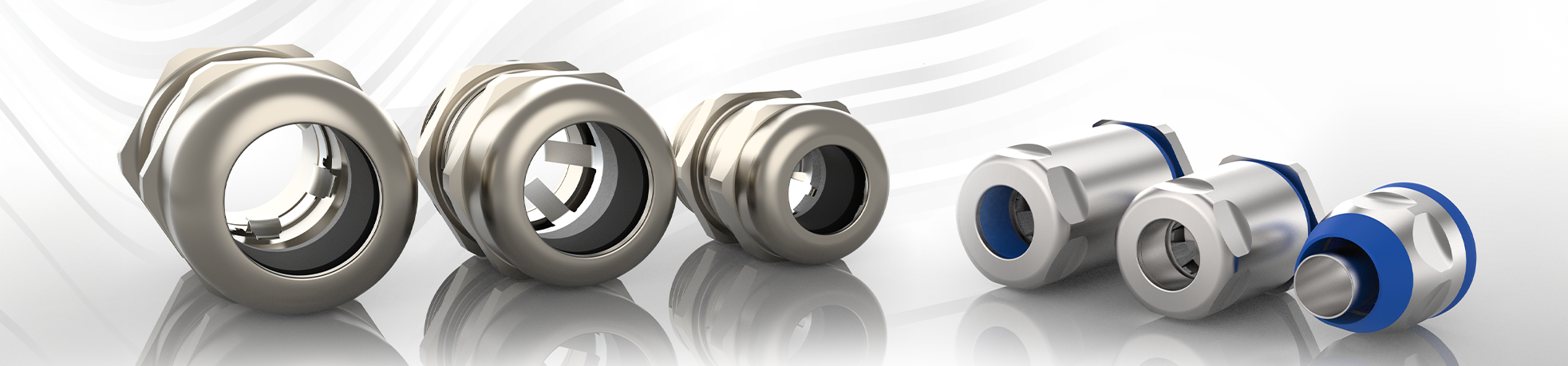

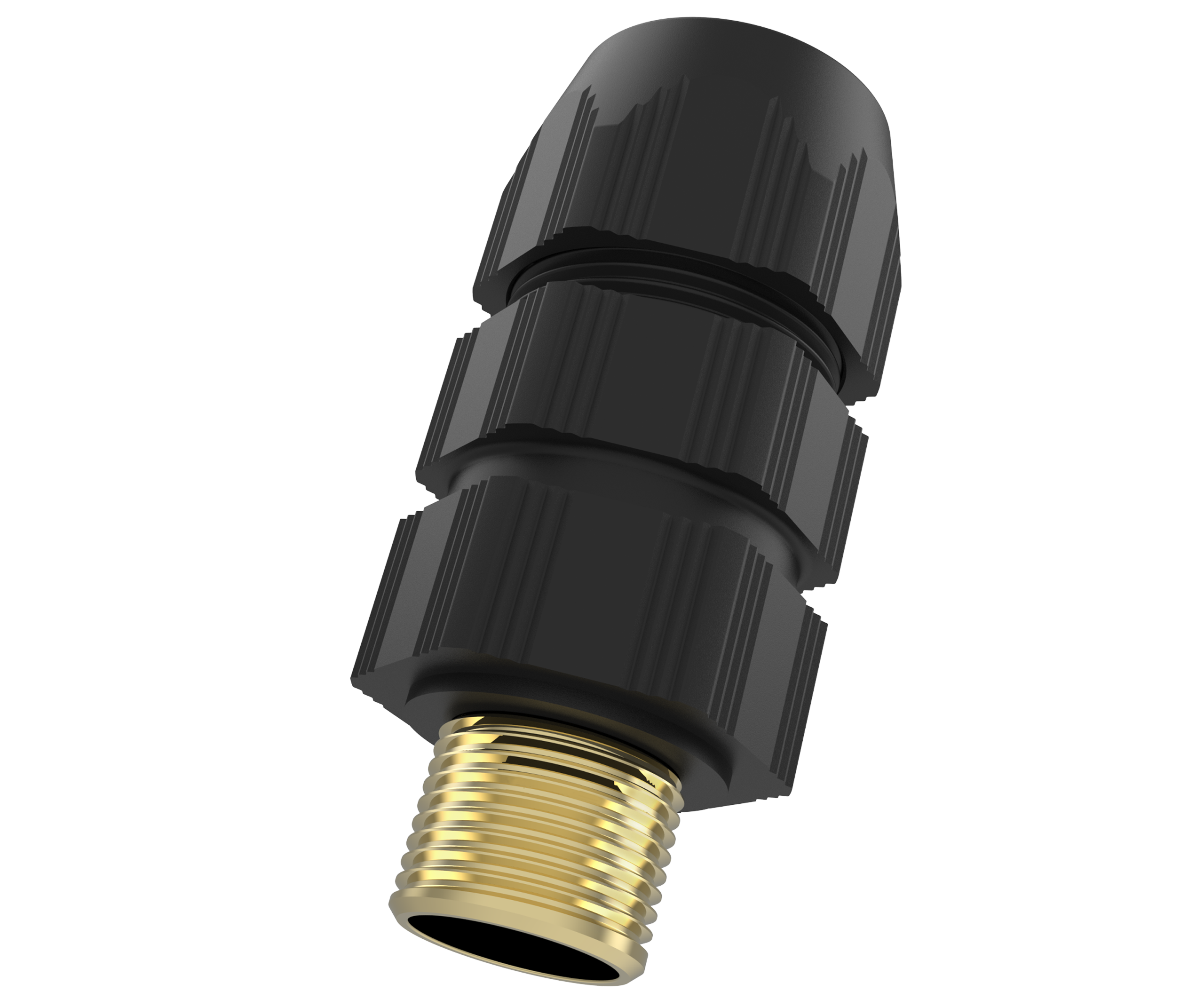

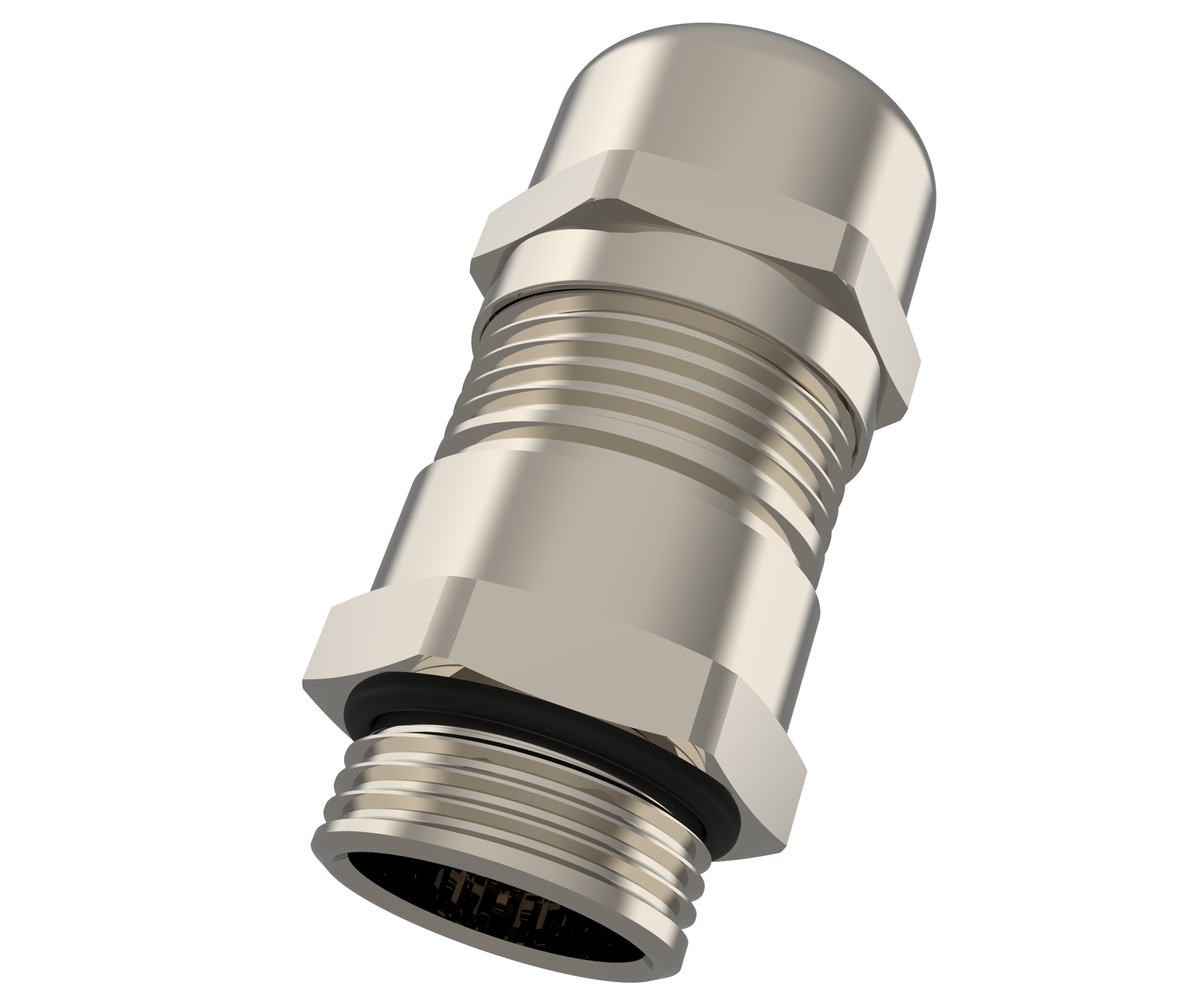

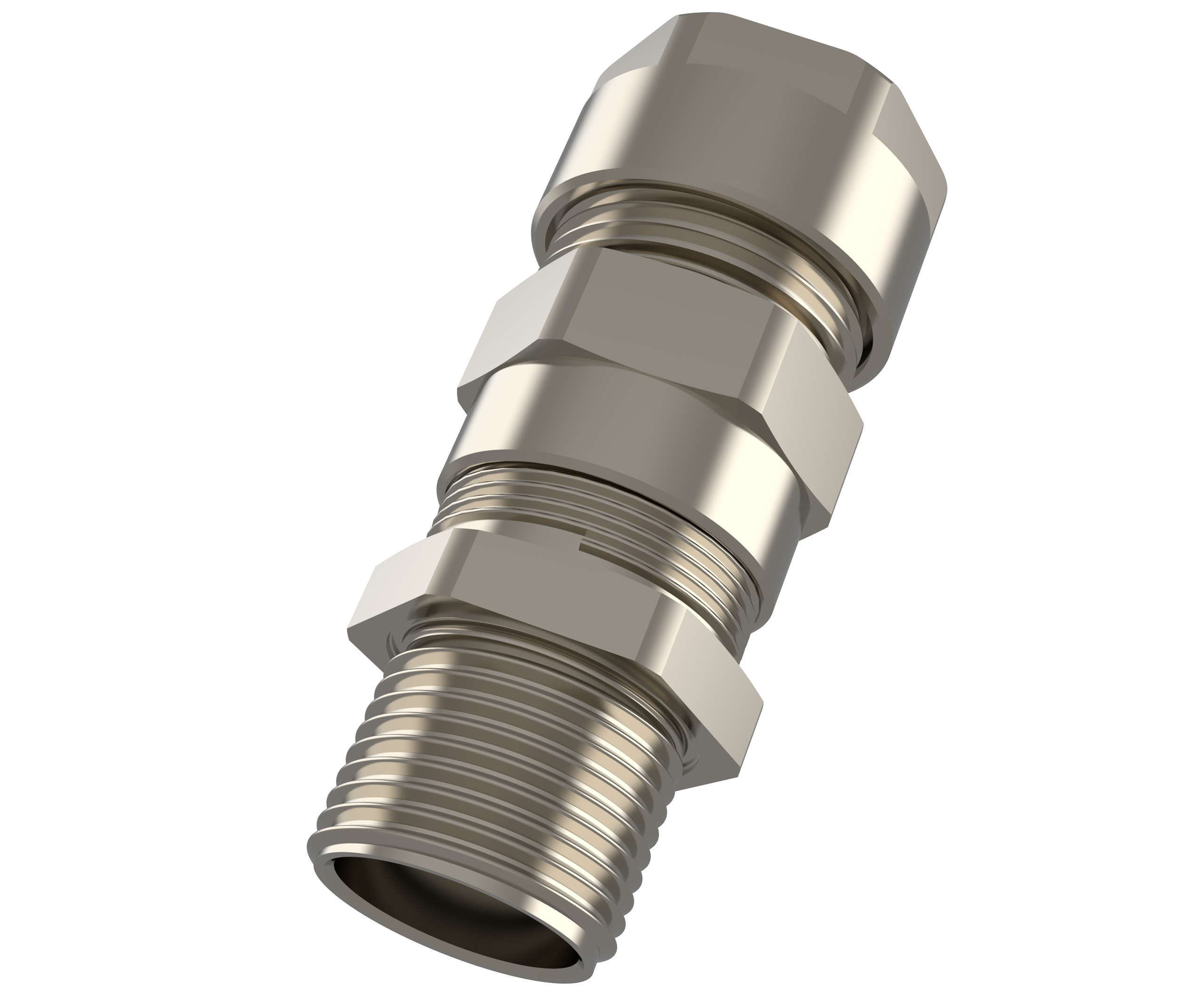

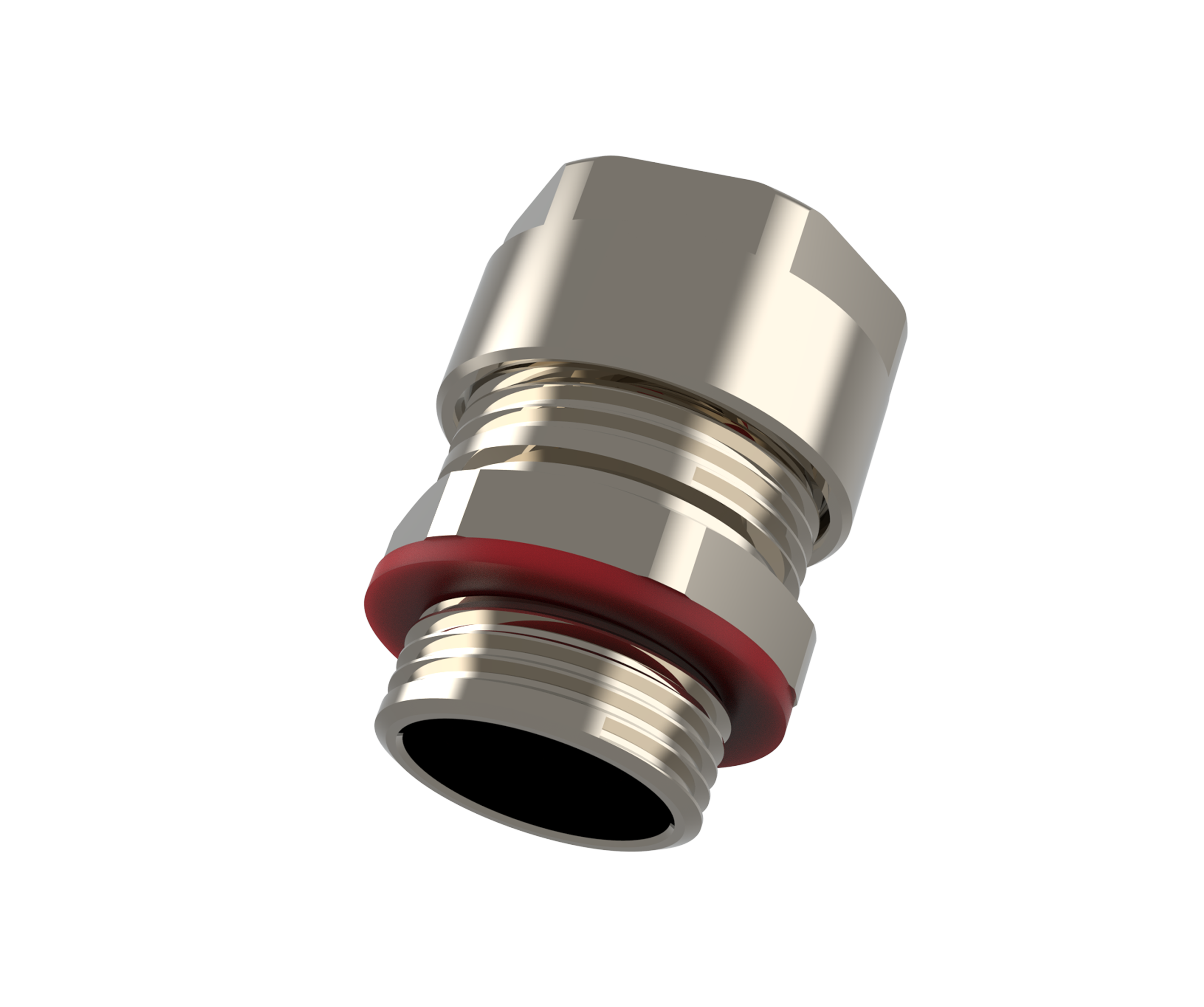

Cable glands play a crucial role in almost all industrial settings by ensuring the safe and

efficient management of electrical cables. These devices provide secure entry points for cables

into electrical equipment, offering protection against environmental factors such as dust,

moisture, and chemicals. By maintaining a proper seal, cable glands help prevent short circuits,

electrical malfunctions, and corrosion, thus enhancing the safety and longevity of electrical

systems. They also offer strain relief, reducing the risk of cable damage due to mechanical

stress, vibration, or movement. In industries like manufacturing, power generation, renewable

energy, and transportation, where electrical systems are exposed to harsh conditions, cable

glands are essential for maintaining the reliability and integrity of operations. Additionally,

they ensure compliance with safety standards, reduce maintenance needs, and minimize downtime,

making them a vital component in the smooth functioning of industrial processes.

More

-30-10-2024-10-05-20.png)

-30-10-2024-10-04-33.png)

.png)